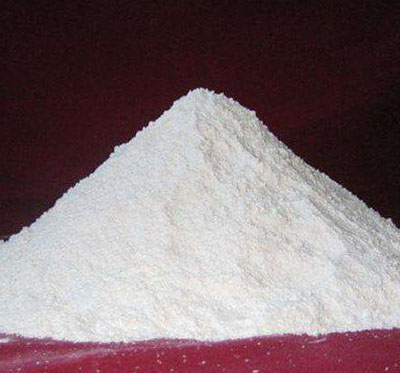

Light burnt magnesium powder is an important refractory material Light burnt magnesium oxide powder is a raw material with medium alkalinity chemical activity. Magnesium ball manufacturers are also used in other industrial fields in addition to refractory materials gelling materials. In addition, the development of converter slag splashing furnace protection technology has further expanded the application range of lightly burned magnesium oxide powder. At present, the slag splashing furnace protection technology mostly uses lightly burned magnesium oxide powder into balls, including lightly burned magnesium oxide powder balls, carbon-containing lightly burned magnesium oxide sub-balls carbon-containing calcium-containing lightly burned magnesium oxide powder balls. Lightly burned magnesium oxide powder, referred to as lightly burned magnesium powder, is a kind of activated magnesium oxide obtained by calcining magnesium hydroxide extracted magnesite, brucite seawater brine at about 800 ~ 1000 ℃.

The light burnt magnesium powder is light yellow light brown powder, the particle size is mostly below 100 mesh, the perovskite crystal is very small. The density of light burnt magnesium ball is prepared by adding 80% light burnt magnesium powder to 2O water The grinder performs rolling, stirring, mixing for 15 to 20 minutes to form a mixture, which is sent to the ball press machine through a belt conveyor to prepare the product, then stacked.

The finished light-burned magnesium ball will be ready for sale after 48 hours of drying forming strength. Improvement of the production process of lightly burned magnesium balls by magnesium ball manufacturers 1 The necessity of improvement of the production process of lightly burned magnesium balls After years of production practice in our factory, lightly burned magnesium ball products are produced according to the above preparation process, the quality of the products has the following problems. 1) The sphere is loose. Low density, low strength easy to break. Especially when loading, unloading, transporting, squeezing falling, the sphere is easy to break. 2) Low ball formation rate. After the raw materials are processed by the ball press machine, half are products half are powder particles. The powder particles need to be manually returned to the ball press machine to continue processing. 3) The user is satisfied. The products sold contain mixtures of 2O% -35% small pieces powders, users have repeatedly disputed this. 4) The shape of the sphere is incomplete. Some are half a ball, some are a third, some have missing corners, different shapes, dull surface, poor appearance.

| Address: Shengshui Village, Nanlou Development Zone, Dashiqiao City |

| Phone: +86 0417-5285999 |

| Fax: +86 0417-5284222 |

| Mobile phone: +86 14704176600 Manager Wang |

| website:www.sxref.cn |

Just scan

Visit mobile website